Our Product Design Capability

Introduction

Product design capability is a pivotal factor in determining a company’s success. It not only allows for internal enhancements to a product’s appearance and quality but also aids in reducing production costs. Externally, a strong design capability empowers a company to innovate and meet market demands, thereby increasing sustainability and gaining a competitive edge while enhancing customer satisfaction. In other words, product design capability doesn’t just optimize products but propels the overall development and success of the company.

Key Aspects of Design Competency

Product design capability is a comprehensive skill that encompasses a systematic design and production process. Within this capability, three critical aspects are essential:

- Effective Communication:Design processes often require close collaboration with various departments within a company, including management, factory divisions (such as plating, tooling, production lines, and quality control). Excellent communication skills are crucial for efficient problem-solving during the product development process. Empathizing with individuals in different roles helps streamline the production process, while reducing unnecessary communication costs.

- Attention to Detail:Accurately describing dimensions and materials is vital, as precise data prevents misunderstandings during production and ensures that products are manufactured according to design specifications.

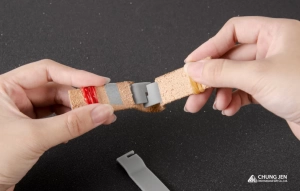

- Patience and Persistence:Early-stage inspection and testing are critical to preventing potential issues in later production, such as discovering that certain production techniques cannot be executed or addressing size discrepancies. Maintaining principles, allowing room for adjustments, and planning for contingencies aid in dealing with uncertainties and ensuring successful product production.

Product Development Process

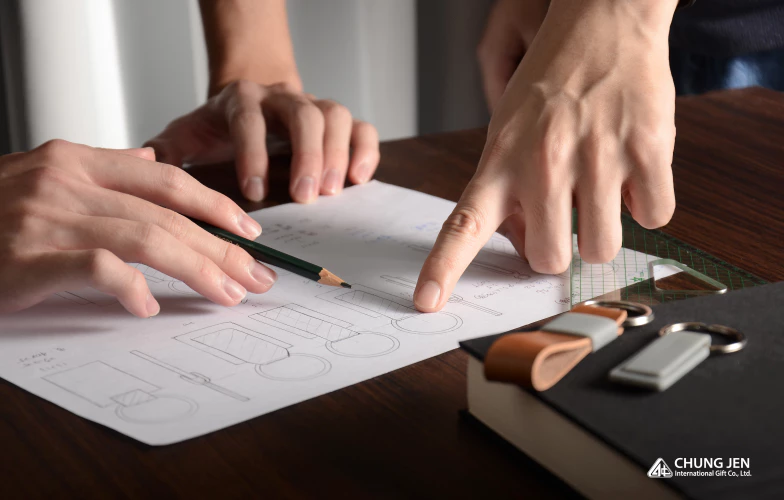

Communication and discussions are the most crucial elements in the entire production process. At each stage, close collaboration and dialogue between the design team and various departments are required to create an ideal product. The generalized product design and development process is as follows:

- Product Positioning/Conceptualization:

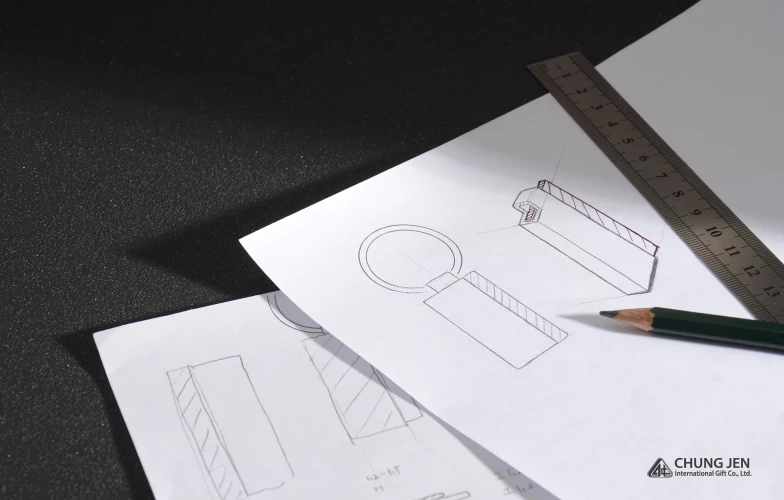

The team considers and defines the product’s position, core concepts, and market needs, unleashing creativity to begin shaping a new product. - Hand-drawn Sketches:

Converting concepts into visual representations often starts with hand-drawn sketches to capture the fundamental appearance and functionality of the product. - Preliminary Model Testing and Evaluation (Paper Models/3D Printing, etc.):

During this phase, preliminary models may be created using various methods, such as paper models or 3D printing, for appearance and functionality evaluations. - Dimension Definition:

Precise dimensions are determined to prepare for further design and actual manufacturing. - Styling Development:

Optimizing the product’s appearance and shape while considering practical usage scenarios. - 3D Modeling: Professional 3D modeling software is used to create precise digital representations of the design for further design and testing.

- Color Setting and Surface Treatment (with Sample Patterns):

Selection of product colors and surface treatment methods to enhance aesthetics and texture, with sample patterns for reference. - Sample Production:

Creating preliminary samples to ensure design and dimension accuracy. - Sample Inspection and Testing:

Inspection and various tests on samples to ensure they meet standards and quality requirements. - Product Launch:

After completing all preparatory work, the product is formally introduced to the market, involving marketing and sales.

Conclusion

We possess excellent design capabilities focused on understanding your ideas and creating customized products to meet your needs. Our professional and creative team has delivered unique products for various brand domains.

Our product offerings primarily consist of zinc alloy metal corporate gifts, along with custom gifts in various materials. Proficient in die-casting, metal plating, and various coloring techniques, we ensure that every detail of the product is perfectly realized. Feel free to share your ideas, and our designers will thoroughly assess your requirements and provide innovative solutions.

With cutting-edge technologies, including 3D modeling and printing, we guarantee high-quality design that meets the rigorous demands of actual production. Partner with us, and you’ll have a team dedicated to details, innovation, and customer experience. Please don’t hesitate to contact us to create exclusive custom corporate gifts.